What Are Brushless DC Motors

What Are Brushless DC Motors

Understanding the concept and application of high-efficiency motors.

A motor converts electric energy to mechanical. Different types of motors are commonly used. Of these, brushesless DC motors (BLDC) have high efficiency as well as excellent controllability. They are frequently used in various applications. The BLDC motor is energy-efficient in comparison to other types of motors.

Motors Are Power Delivery Machines

When engineers face the problem of designing electrical devices to accomplish specific mechanical functions, they may be thinking about the way electrical signals are transformed into energy. Motors and actuators are among the equipment that convert electrical signals to motion. Motors convert electrical energy to mechanical energy.

The most basic type that motors are available is the brush DC motor. In this kind of motor, electric current is pushed through coils that are placed in an unchanging magnetic field. The current creates magnetic fields within the coils, which results in the coils to turn, as each coil is pulled away from the similar pole and pulled towards the opposite one of the field fixed. In order to maintain the rotation it is essential to constantly reverse the current so that the polarities of the coils will constantly shift which causes the coils to keep “chasing” the unlike fixed poles.

The coils are provided by fixed conductive brushes which are in contact with a commutator that is rotating; it is the movement of the commutator that triggers the reverse of current that flows through the coils. The commutator as well as the brushes are the primary components that distinguish the brush-driven DC motor and other kinds. In Figure 1, we can see the basic concept of the brushed motor.

Common Motor Types - Different Types of Motors

Brushed DC motors, which feature an easy-to-use design and simple control, are extensively employed for opening and closing disk tray. In automobiles they are frequently employed for retracting, expanding and even putting up electrically powered side windows. Their low price motors make them ideal for a variety of applications. The only drawback is that commutators and brushes tend to wear quickly due to their constant contact, which requires regular replacement and maintenance.

Stepper motors are controlled by pulses, and it moves around a predetermined angle (step) each time it receives a pulse. Since the speed of rotation is controlled by the amount of pulses received they are commonly utilized to control positional adjustments. They are frequently utilized, for instance to control the flow of paper in printers and fax machines since they feed paper in specific steps that are easily linked to pulse count. Pauses can also be managed, since motor rotation stops immediately whenever the pulse signal is stopped.

In synchronous motors, rotation is synchronized to the frequency of supply current. These motors are commonly employed to drive the rotating tray in microwave ovens. Reduction gears within the motor unit are employed to get the right speed of rotation to cook food items. Induction motors as well, the speed of rotation changes with frequency, however the movements are not synchronized. In the past the motors were typically employed in electric fans and washing machines.

There are a variety of motors that are used in everyday use. In this presentation we will look at the benefits and uses that brushes less DC motors.

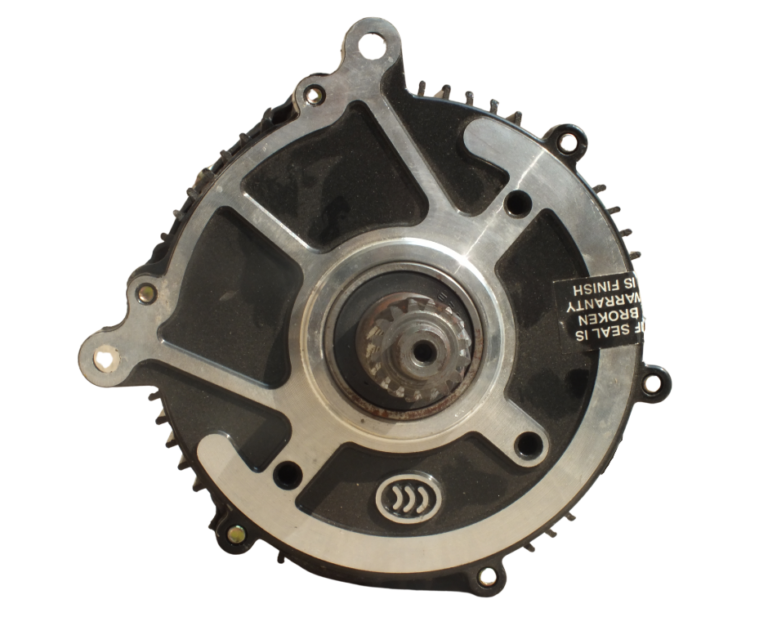

Why Do BLDC Motors Turn?

The name suggests that brushless DC motors do not employ brushes. When a motor is brushed, the brushes transmit current through the commutator to the rotor’s coils. How does the brushless motor deliver current to the rotor’s coils? It’s not possible because the coils aren’t located in the rotor. In fact, it is the stator that acts as a permanent magnet. The coils don’t rotate however, they are fixed in position on the stator. Since the coils don’t move they do not require for brushes or a Commutator.

The brushed motor’s it is possible to control the magnetic fields produced by the coils that are on the rotor. However, the magnetic field produced by stationary magnets remains constant. To alter the speed at which the motor rotates you need to alter the voltage of the coils.

When you use the BLDC motor, it’s the permanent magnet which rotates and it does this by altering the direction of magnetic fields produced by the nearby stationary coils. To regulate the speed of rotation you have to adjust the strength as well as the direction that current flows flowing through the coils.

Advantages of BLDC Motors

A BLDC motor that has three coils in the stator would have 6 electric wires (two for each coil) connecting the coils. In the majority of cases, the three wires are connected to the internal circuit, with the remaining wires running out of the body of the motor (in opposition to two wires running through the brush motor mentioned earlier). The wiring in the BLDC motor’s case is more complex than just connecting the power cell’s negative and positive terminals. We’ll investigate the ways in which these motors function in the next part in this sequence. In the next section, we will conclude by examining the benefits of BLDC motors.

One major benefit is their efficiency, since these motors are able to operate continuously at the maximum force of rotation (torque). Motors that are brushed, on the other hand have maximum torque only at certain places in the rotation. To provide the same amount of torque like a brushless motor is to utilize larger magnets. This is the reason even small BLDC motors can produce a lot of power.

The other major benefit–which is related to the first one is the controllability. BLDC motors are able to be controlled by through feedback mechanisms, to provide precisely the torque and speed of rotation. Controlling precision decreases the energy use and heat production, and in instances where the motors are battery-powered, extends battery’s lifespan.

BLDC motors also provide excellent durability and a low noise, due to the absence of brushes. When using brushed motors, the commutator’s brushes and brushes wear out as a result of constant contact as well as sparks are generated when contact occurs. The noise that is generated by electrical current, particularly it is caused by the intense sparks that are typically found in the points where the brushes cross the gaps of the commutator. This is the reason BLDC motors are generally thought of as the best choice in cases in which it is essential to reduce electrical noise.

Ideal Applications for BLDC Motors

We’ve noticed that BLDC motors are highly efficient and control, and they are able to last a long life. What do they work for? Due to their effectiveness and long-lasting nature they are frequently employed in devices that operate constantly. They’ve been in use for a long time to power air conditioners, washers and various other electronic devices for consumers as well as, more recently they have been appearing in fans, where their superior efficiency has resulted in significant reductions in energy consumption.

They can also be utilized to drive vacuum machines. In one instance an adjustment to the control program caused significant increases in the speed of rotation, a signification of the incredibly precise control that these motors provide.

BLDC motors also are utilized to spin hard disk drives. Their endurance ensures that the drives will continue to function for a long time and their power efficiency aids in reductions in energy consumption in a field that is becoming more crucial.

Toward Wider Usage in The Future

We could be seeing BLDC motors being used in a variety of future applications. For instance, they’ll likely be used extensively to drive service robots, which are small robotics that offer services outside of manufacturing. It is possible to believe that stepper motors will be better suited to this kind of scenario as pulses can be utilized to precisely control the movement.

However, BLDC motors are more suitable for controlling force. With a stepper motor controlling the location of a structure like the robot arm will require a large and constant current. With the BLDC motor the only thing required is a proportionate current to the force externally applied, allowing for more efficient control. BLDC motors might also replace brush dc motors that are used in mobility and golf carts. Alongside their superior performance, BLDC motors can also provide more precise control, which could in turn extend the life of batteries.

BLDC motors can also be suitable for drones. Their ability to provide precise control makes them ideal for multicolor drones where the drone’s movement is controlled precisely by controlling the speed of rotation for each of the rotors.

In this presentation we’ve learned that BLDC motors are extremely efficient in terms of controllability, longevity, and reliability. However, careful and precise control is crucial to take the full benefit of the motor’s potential. In our next class we will explore how these motors function.

Keywords : bldc motor, brushless dc bldc motor, bldc motor price, bldc motor and controller, 48v bldc motor controller, 48v bldc motor and controller, bldc motor manufacturer, bldc electric motor, bldc motor manufacturing, bldc motor supplier, dc motor manufacturers, dc motor manufacturers in india, bldc motor manufacturers in india, brushless dc motor manufacturers, bldc motor suppliers, brushless dc motor suppliers, bldc motor controller manufacturers, erickshaw motor manufacturer, rickshaw electric motor, e rickshaw motor price, e rickshaw motor kit price, electric vehicle motor manufacturers, e rickshaw motor manufacturers in india, e rickshaw motor manufacturers in delhi, electric rickshaw motor manufacturers in india, e loader motor, e loader motor manufacturer, e loader motor manufacturer in india, e loader motor supplier, e loader motor supplier in india, best electric vehicle equipment manufacturer & supplier company in india, best electric vehicle equipment manufacturer company in india, best electric vehicle equipment supplier company in india, best electric vehicle equipment at lowest price in india, buy best electric vehicle equipment with affordable price in india, best electric vehicle equipment at cheapest price in india, best electric vehicle equipment in india, best ev equipment manufacturer & supplier company in india, best ev equipment manufacturer company in india, best ev equipment supplier company in india, best ev equipment at lowest price in india, buy ev equipment with affordable price in india, best ev equipment at cheapest price in india, best ev equipment in india, best electric vehicle equipment manufacturer & supplier in india, best ev equipment manufacturer & supplier in india, best e rickshaw motor manufacturer company in india, best e rickshaw motor manufacturing company in india, best e rickshaw motor manufacturer & supplier company in india, best e rickshaw motor supplier in india, best e rickshaw motor at lowest price in india, best e rickshaw motor with affordable price in india, buy e rickshaw motor at best price, buy e rickshaw motor at cheapest price, e rickshaw motor, best e rickshaw motor manufacturing company in india, best e rickshaw motor manufacturer compnies in india, best e rickshaw motor for lowest price in india, best e rickshaw motor manufacturer in india, e rickshaw motor price in india, bldc motor, brushless dc bldc motor, bldc motor price, bldc motor and controller, 48v bldc motor controller, 48v bldc motor and controller, bldc motor manufacturer, bldc electric motor, bldc motor manufacturing, bldc motor supplier, dc motor manufacturers, dc motor manufacturers in india, bldc motor manufacturers in india, brushless dc motor manufacturers, bldc motor suppliers, brushless dc motor suppliers, bldc motor controller manufacturers, erickshaw motor manufacturer, rickshaw electric motor, e rickshaw motor price, e rickshaw motor kit price, electric vehicle motor manufacturers, e rickshaw motor manufacturers in india, e rickshaw motor manufacturers in delhi, electric rickshaw motor manufacturers in india